- 16 February 2026

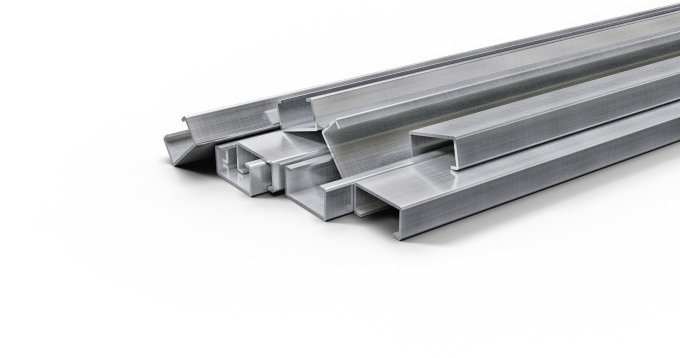

Aluminum profiles are a key component in many areas of industry and construction. Their strength is extremely important for effective and durable construction.

Aluminum profiles are building components made of aluminum. Their strength is one of the most important parameters that are paid attention to in the design and selection of materials in structures. Various factors can affect the strength of aluminum profiles, such as the shape, thickness, or type of aluminum used in production.

The strength of these profiles is decisive for construction, such as windows, doors, industrial structures or aluminum systems in architecture. An aluminum profile must be strong enough to support loads, resist weathering and remain durable for a long time.

Choosing the right type of aluminum is crucial to the strength of aluminum profiles. There are several types of aluminum, which differ in the degree of strength, corrosion resistance and other mechanical properties. Aluminum-silicon alloy (AlSi), aluminum-magnesium alloy (AlMg), or aluminum-copper alloy (AlCu) are mainly used in the production of aluminum profiles. Each of these alloys has its own characteristics, which affects the strength and end-use of the profiles.

The geometry of aluminum profiles has a significant impact on their strength. A profile with a properly designed shape and structure is able to effectively carry loads. Elements such as wall thickness, transverse shape and the number of stiffeners have a significant impact on the load-bearing capacity of aluminum profiles.

Atmospheric conditions, such as humidity, temperature and the presence of corrosion, can significantly affect the strength of aluminum profiles. Aluminum is naturally resistant to corrosion, but prolonged exposure to extreme weather conditions can affect its strength. Therefore, an aluminum profile used outdoors or in areas with high humidity must be properly protected to maintain its properties for many years.

Aluminum profiles are widely used in residential construction. They are used for windows, doors, balustrades or building facades. Their strength, lightness and weather resistance make them a popular choice for both new developments and renovations.

In industry, heavy-duty aluminum profiles are used as structural elements in machine manufacturing, steel structures or transportation systems. Their lightness, strength and ease of processing make them a valued material in a variety of industries.

In the automotive sector, aluminum profiles are used for vehicle frames, bodies or interior components. Their high strength while maintaining low weight contributes to improved vehicle performance and reduced fuel consumption.

Thanks to technological advances in manufacturing, the strength of aluminum profiles is constantly improving. Modern technologies make it possible to precisely form aluminum, resulting in improved material structure and strength. In addition, innovations in the surface treatment of aluminum increase its resistance to corrosion, resulting in a longer life of the profiles.

Research on aluminum and profile manufacturing processes is focused on continuously improving its strength. With the involvement of scientists and engineers, experiments are being conducted on new aluminum alloys that can provide even better strength characteristics. Cooperation between universities and industrial companies is aimed at creating materials that are even tougher, but still maintain their favorable properties.

Checking the strength of aluminum profiles is done by conducting laboratory tests. These methods include tensile, bending, or torsion tests to determine the strength parameters of the material. Such tests allow manufacturers and engineers to determine the limits of the material's load and strength, which is important for structural design.

An important element confirming the strength of aluminum profiles are certificates and compliance with quality standards. Manufacturing in accordance with relevant standards ensures that aluminum profiles meet specific strength criteria and are safe for use. Certificates confirming the quality of materials are important for both manufacturers and customers, guaranteeing the high quality of products.

The strength of aluminum profiles plays a key role in various fields of industry and construction. Their versatile use, strength and development possibilities make them an indispensable material in many construction projects. In Poland, their popularity is steadily growing, with new production technologies and scientific research focused on constantly improving strength parameters. Durable aluminum profiles are not only a symbol of solidity, but also of ecology and sustainable development.